Each year the Smart Business Recycling Program recognizes outstanding waste reduction & recycling efforts throughout South Carolina. The state has a goal to recycle 50 percent of waste generated by 2030 - echoing EPA's recycling goal - which can only be accomplished if businesses recycle and report their progress. Smart Business Recycling Award applicants are required to report their recycling efforts and data for the S.C. Solid Waste Management Annual Report. Click the button above to download the application and submit to smartbiz@dhec.sc.gov.

2022 Award Winners

Columbia Metropolitan Convention Center (Richland County)

The Columbia Metropolitan Convention Center (CMCC) in Columbia excels in waste reduction and recycling. CMCC hosts every event imaginable, from receptions and cultural galas to corporate functions and international trade shows, and can adapt to the needs of most any meeting. The facility recycles commodities including paper, plastic, aluminum, glass, steel, and even oyster shells. Food waste is prevented by confirming catering headcounts seven days before an event, and unavoidable food waste is recovered through composting. The facility boasts Low E glass and low-flow restroom facilities, and all of the lighting has been converted to LED, which has led to a 67 percent reduction in energy usage. CMCC staff take care to educate their employees and clients on their green initiatives and ask them to assist in upholding practices while in the facility.

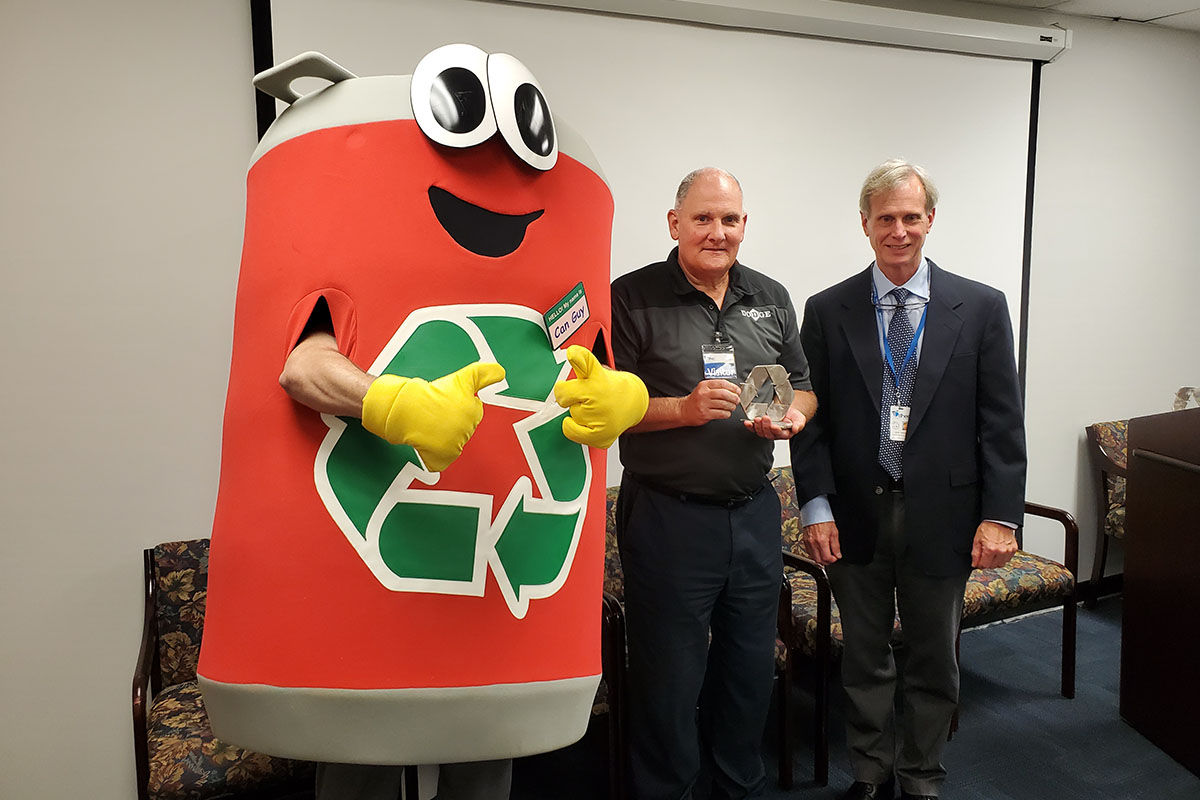

Dodge Mechanical Power Transmission Greenville Gear Plant (Greenville County)

The Dodge Mechanical Power Transmission Greenville Gear Plant in Greenville is a gearbox manufacturing facility focused on making products for conveyor, mining, and aggregate industries. To date, Dodge’s Zero Landfill Initiative has led to 91 tons of landfill waste being recycled into energy. Other waste reduction efforts include recycling scrap metal, wood, batteries, electronic scrap, hazardous waste, and used oil. Green infrastructure features a closed-loop cooling tower used for water conservation and a computerized building management system that allows for heating and cooling energy conservation during non-occupied times. Employees at Dodge are trained on its Zero Landfill Status goal and participate in recycling and Earth Day events. Dodge provides mentoring in the community and to its other facilities on sustainable practices.

Shutterfly (York County)

Shutterfly creates customized personal products and photography, and the York County location specializes in manufacturing e-commerce products. Shutterfly’s Quality Team provides regular upstream inspections on calibration and operator training to help reduce material having to be reprinted. They are dedicated to using recycled packaging, testing new technology for making recycled paper products, and recycling items such as paper, cardboard, plastic, and wood. Shutterfly donates the slight quality defect or excess inventory waste to local non-profits including Habitat for Humanity, Anne Close Springs Greenway, ReCraft, and Kids-In-Need Foundation. Through collecting data and using energy-efficient practices including LED retrofitting, equipment upgrades, and building management programs, Shutterfly has been able to reduce its energy use 1% year-over-year. Employees also have participated in recycling-based trainings, a yearly recycling/waste audit, and have built creation kits for local schools using waste from the production floor.

Congratulations to the 2022 Smart Business winners! DHEC commends their efforts in helping to pursue the agency’s mission of promoting and protecting the health of the public and the environment.

Contact Info

Email smartbiz@dhec.sc.gov or call 1-800-768-7348.